When installing or upgrading an HVAC system, understanding the types of commercial HVAC ducting is essential. Ductwork is more than just a series of tubes; it’s the delivery system for your building’s indoor comfort. Choosing the wrong type can lead to higher energy bills, poor airflow, or even costly repairs.

If you’re unsure where to start, don’t worry. There are three basic types of commercial HVAC ducting commonly used across offices, warehouses, retail spaces, and more. Each has its strengths depending on layout, noise control, and energy efficiency.

Let’s explore your options and how to choose what’s best for your building.

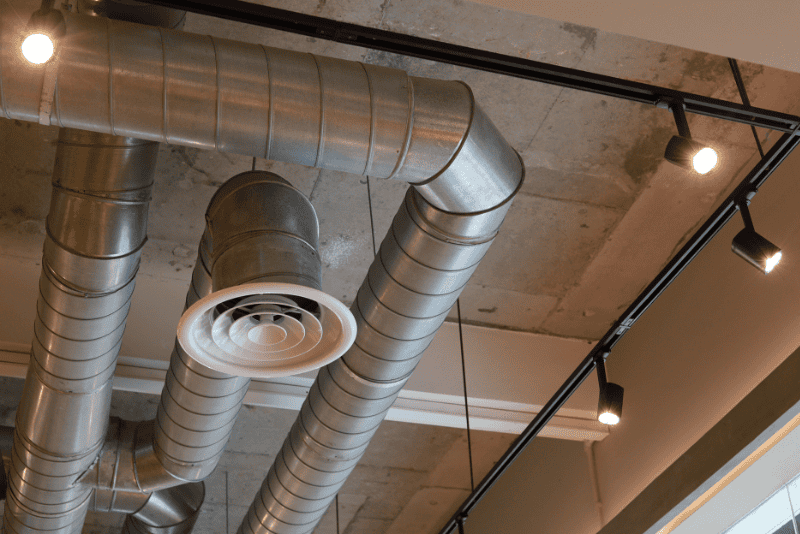

Sheet Metal Ducts: Durable and Long-Lasting

Sheet metal ductwork is the most common and widely used type in commercial HVAC systems, typically made from galvanized steel or aluminum. These ducts are extremely durable, fire-resistant, and offer smooth interiors that promote efficient airflow throughout the building. While installation can be more labor-intensive, sheet metal ducts are ideal for large spaces that need reliable, long-term performance.

Benefits:

- Smooth interior for efficient airflow

- Resistant to mold and bacteria

- Extremely durable and fire-safe

- Easy to clean and maintain

Best For:

- Large commercial buildings

- Spaces with high air volume needs

- Long-term systems requiring minimal maintenance

Keep in mind that installation costs may be higher due to the rigid nature and labor involved, but the payoff in performance is worth it.

Flexible Ducts: Great for Tight or Curved Spaces

Flexible ducts are made from a metal wire coil wrapped in plastic and insulation, making them lightweight and easy to maneuver. They’re perfect for navigating tight spaces or connecting registers to main duct lines where rigid systems won’t fit. Although they’re more affordable and easier to install, they can be prone to airflow restrictions if not properly supported or straightened during installation.

Benefits:

- Lower cost and faster to install

- Easily fits around obstacles or in tight areas

- Lightweight and adjustable

Best For:

- Smaller commercial spaces or retrofits

- Connecting main ducts to vents or registers

- Spaces where noise is less of a concern

However, airflow can be restricted if the duct isn’t installed correctly—sagging or sharp bends can lower efficiency.

Fiberglass-Lined Ducts: Noise-Reducing and Insulating

Fiberglass-lined ducts come in two forms: sheet metal ducts with internal fiberglass lining or ducts made entirely of fiberglass board. These systems are excellent for reducing noise and improving thermal insulation, making them ideal for offices, classrooms, or any sound-sensitive environment. However, they require routine maintenance to prevent dust buildup or potential mold growth on the fiberglass surface.

Benefits:

- Helps reduce HVAC noise (great for offices, schools, theaters)

- Built-in thermal insulation improves energy efficiency

- Minimizes condensation in humid environments

Best For:

- Buildings where acoustic comfort is important

- Indoor areas with high humidity

- Zones requiring improved thermal control

A word of caution: if not maintained properly, fiberglass surfaces can collect dust and mold. Regular inspections and cleaning are a must.

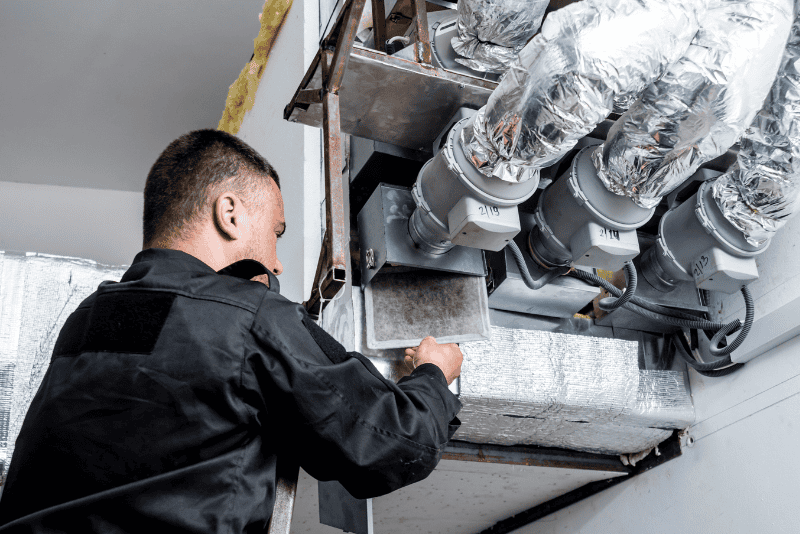

Installation & Maintenance Considerations

While each duct type serves a specific purpose, proper installation and ongoing maintenance are what truly determine long-term performance. Here’s what you need to know for each system:

Sheet Metal Ducts

- Installation: Requires professional tools and expertise to fabricate and install correctly. Best suited for open areas with room for rigid layouts.

- Maintenance: Easy to inspect and clean due to smooth surfaces; resistant to mold and pests.

- Keep in mind: Higher upfront labor and materials cost, but excellent long-term durability and efficiency.

Flexible Ducts

- Installation: Lightweight and easy to install, great for weaving through small or oddly shaped areas.

- Maintenance: Must be properly supported to prevent sagging, air restriction, or damage.

- Keep in mind: While low-cost and quick to install, improper handling can lead to reduced airflow or energy inefficiencies.

Fiberglass-Lined Ducts

- Installation: Often used where sound and temperature control are priorities. Can be lined with sheet metal or duct board.

- Maintenance: Needs regular inspection to avoid dust buildup and potential mold growth on insulation.

- Keep in mind: Not recommended in environments with high particulate matter unless maintenance is strictly followed.

Quick Comparison: Types of Commercial HVAC Ducting

Here’s a snapshot of each duct system’s core strengths to help you make a fast, informed decision:

| Duct Type | Key Advantage | Best Used In |

| Sheet Metal | Strong, durable, efficient airflow | Warehouses, large offices, high-performance systems |

| Flexible Ducts | Easy to install in tight spaces | Renovations, small buildings, hard-to-reach zones |

| Fiberglass-Lined | Quiet and thermally insulated | Schools, offices, theaters, acoustic-priority areas |

Conclusion

Selecting the right types of commercial HVAC ducting ensures that your system runs efficiently, quietly, and safely. Each duct type offers specific benefits depending on your building’s size, layout, and functional requirements. In addition to performance, it’s also important to consider how your ductwork impacts overall indoor air quality, especially in commercial environments where occupant health is a priority.

Before making a final decision, consult with a licensed HVAC professional to evaluate your space and recommend the ideal system for long-term comfort and performance.